Case Study

PLT Packaging Overhaul

Operational Performance Outcomes

Transformed a fragmented packaging workflow into a unified global design system, enabling rapid product launches and reducing print error rates.

40% Reduction in Vendor Approval Cycles

700+ SKUs Standardized Globally

100% Visual Match Across Vendors

Project Overview

As part of a comprehensive rebrand, I led the full redesign of packaging across PLT and PremiumSpec product lines. This effort modernized the look and feel of the brand, ensured consistency across hundreds of SKUs, and elevated the customer experience while improving internal workflows. The packaging system now reflects both the quality of the product and the professionalism of the brand it represents.

The Challenge

As the proprietary PLT line expanded to 700+ SKUs, ad-hoc design processes created a scalability bottleneck. Inconsistent vendor outputs and slow approval loops threatened launch timelines and eroded brand trust at the shelf.

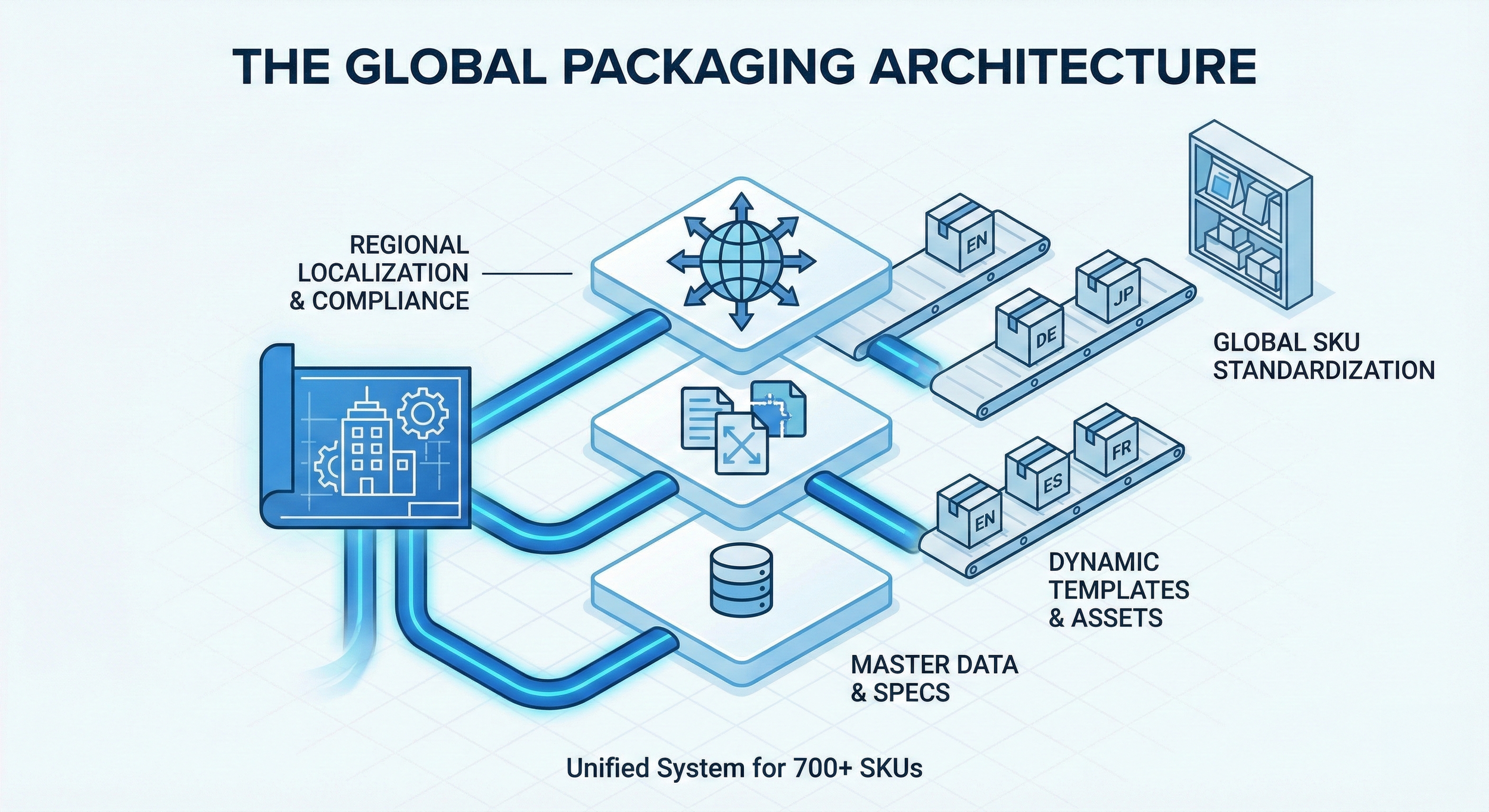

The Global Packaging Architecture

I architected a modular design system that decouples 'Brand Elements' from 'Variable Spec Data.' This allowed us to apply a single master template across hundreds of form factors (boxes, blisters, sleeves) instantly.

Vendor Compliance Protocol: Established a rigorous 'Golden Sample' review process and ink specification standard to ensure manufacturing partners in different regions produced identical results.

My Role:

Directed the end-to-end packaging lifecycle, from structural strategy to final print production, coordinating between Product Management, Overseas Manufacturers, and Creative teams.

Final Takeaway

This project transformed packaging from a production afterthought into a powerful brand asset. By building a scalable, flexible, and brand-aligned packaging system, we not only improved internal workflows but also gave PLT a credible and cohesive presence across every box and shelf.